Additive manufacturing services are speeding up product design and development processes with broad acceptance across industries. By using 3D modeling services, additive manufacturing enables businesses to create tools on-demand, and with multiple design iterations in the time taken to procure a single tool conventionally.

Cyient DLM provides end-to-end solutions and expertise in both polymer and laser metal 3D printing services. With a designated tooling design team of 100+ engineers, we leverage opportunities that technology offers by adding value to an existing part such as weight reduction, enhanced performance, part consolidation, reduced costs, and shorter lead times.

We help customers reduce costs and create more value by providing an alternative to conventional manufacturing processes through our specialized 3D modeling services.

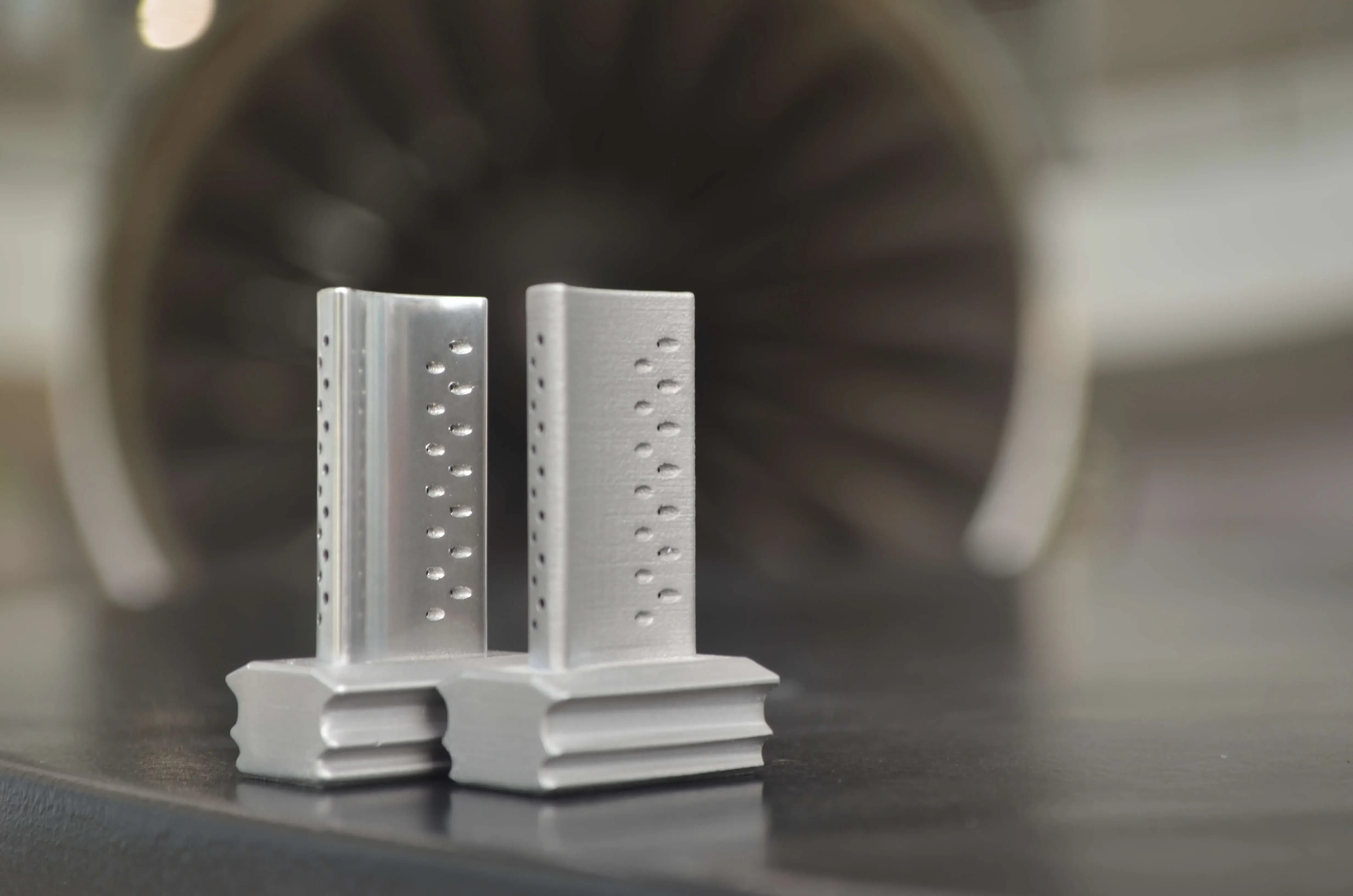

Customers can improve tool performance and increase throughput with a more uniform and quick cooling mechanism around the manufactured component by leveraging our additive manufacturing services that incorporate conformal cooling.

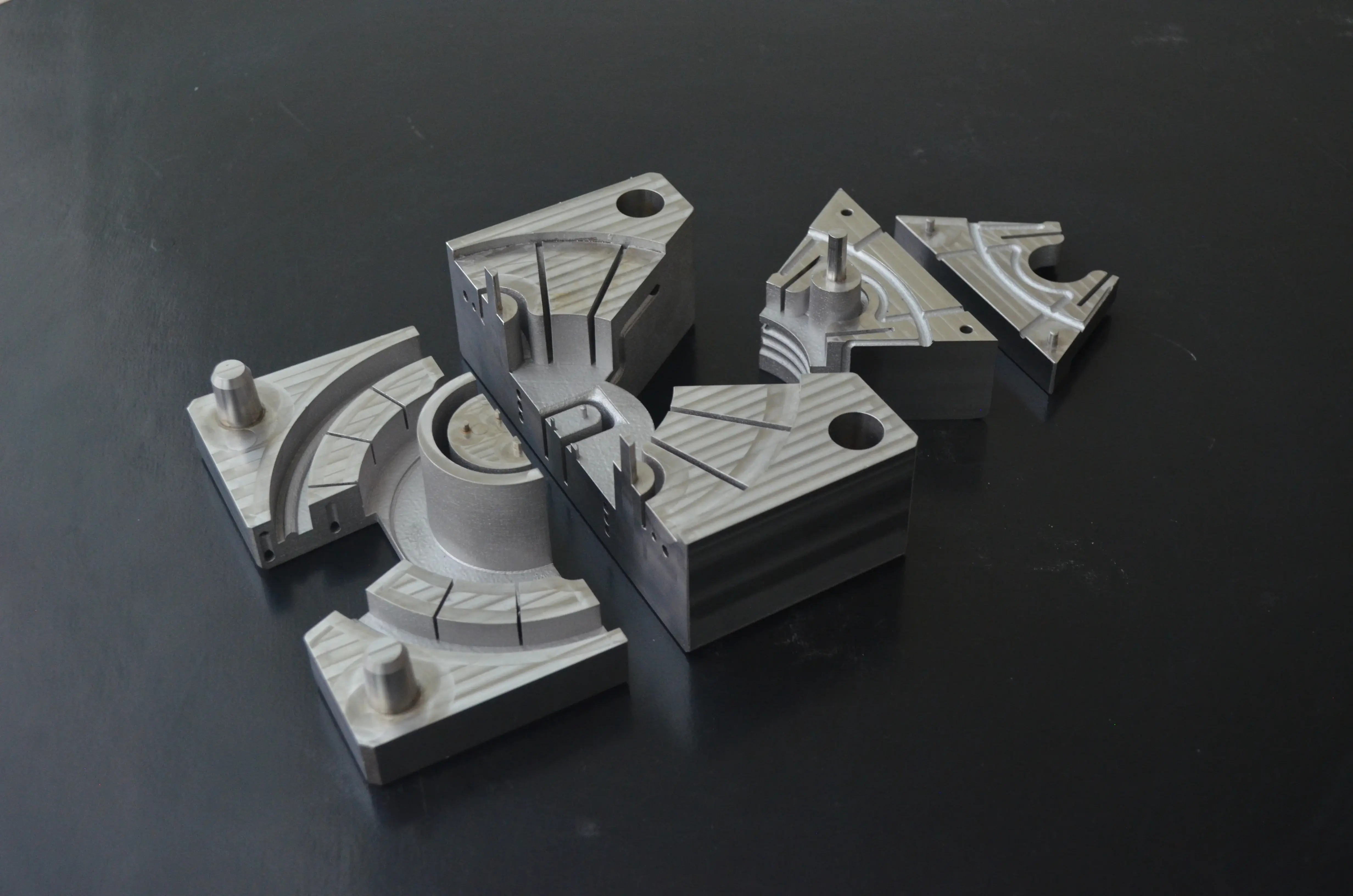

We deliver the finest quality by taking complete ownership of tooling component optimization. This includes high-strength tool design and fabrication with a detailed inspection and test reports.

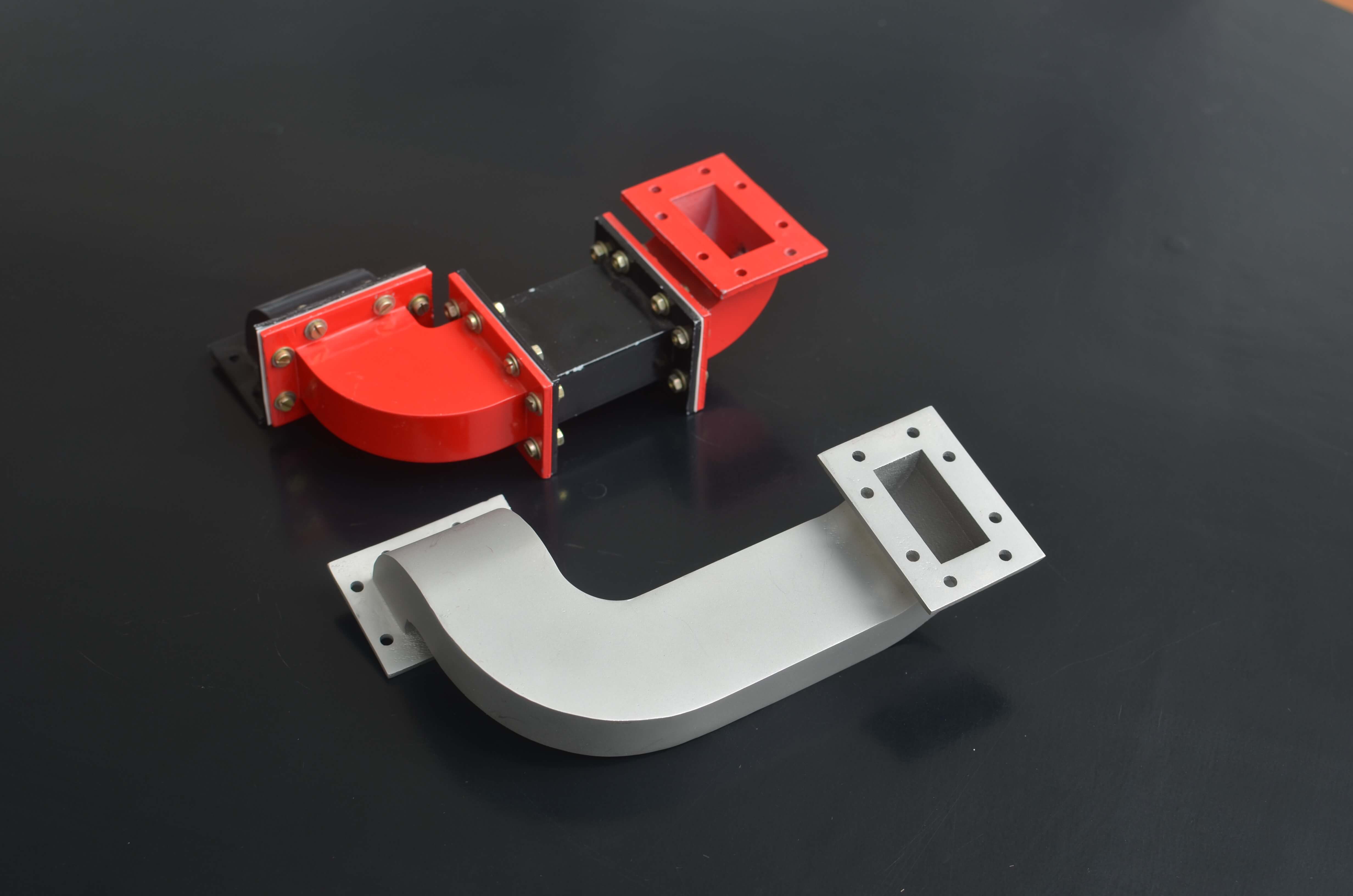

Boost efficiency and reduce lead times for the design and production of specialized tools, gauges, fixtures, jigs, and casings by leveraging our in-house additive manufacturing services.

Reducing 1 kg in weight can lead to $10,000 saved over the life of an aircraft.

Fewer parts, streamlined supply chain, and lower inspection time.

Higher buy-to-fly ratio. Significant savings on expensive materials such as titanium alloys (conventional BTF ratio of 20:40 for milling process versus additive manufacturing’s BTF ratio of 1.3:3).

Ease of manufacturing highly-optimized designs that are fit for function.

Developmental tooling, prototypes, spares, and custom medical parts can be made at a lower cost compared to traditional manufacturing.

On-demand manufacturing reduced dependency on job holding tools, fixtures, and more.

Conformal cooling, smoother flow passages, high SA/V heat exchangers are examples.

Creating a digital inventory for reduced warehousing costs and enhanced logistics.

Discover how Cyient’s end-to-end additive manufacturing solutions and services deliver multiple advantages in the design and production of tooling components.

Cyient DLM (Estd: 1993 ) is a Electronic Manufacturing Services Company

© Cyient DLM 2022. All Rights Reserved.